item |

value |

Pressure |

High |

Place of Origin |

Shanghai, China |

Model Number |

steel argon cylinder |

Material |

Steel |

Brand Name |

BEYIWOD |

Use |

Oxygen |

Material |

seamless steel cylinder |

Place of origin |

Shanghai, China (mainland) |

Water Capacity |

40L 47L 50L |

Working Pressure |

150bar / 200bar |

Test Pressure |

250bar / 300bar |

Outside Diameter |

219MM/232MM |

Wall thickness |

5.2mm/5.4mm/5.7mm/5.8mm |

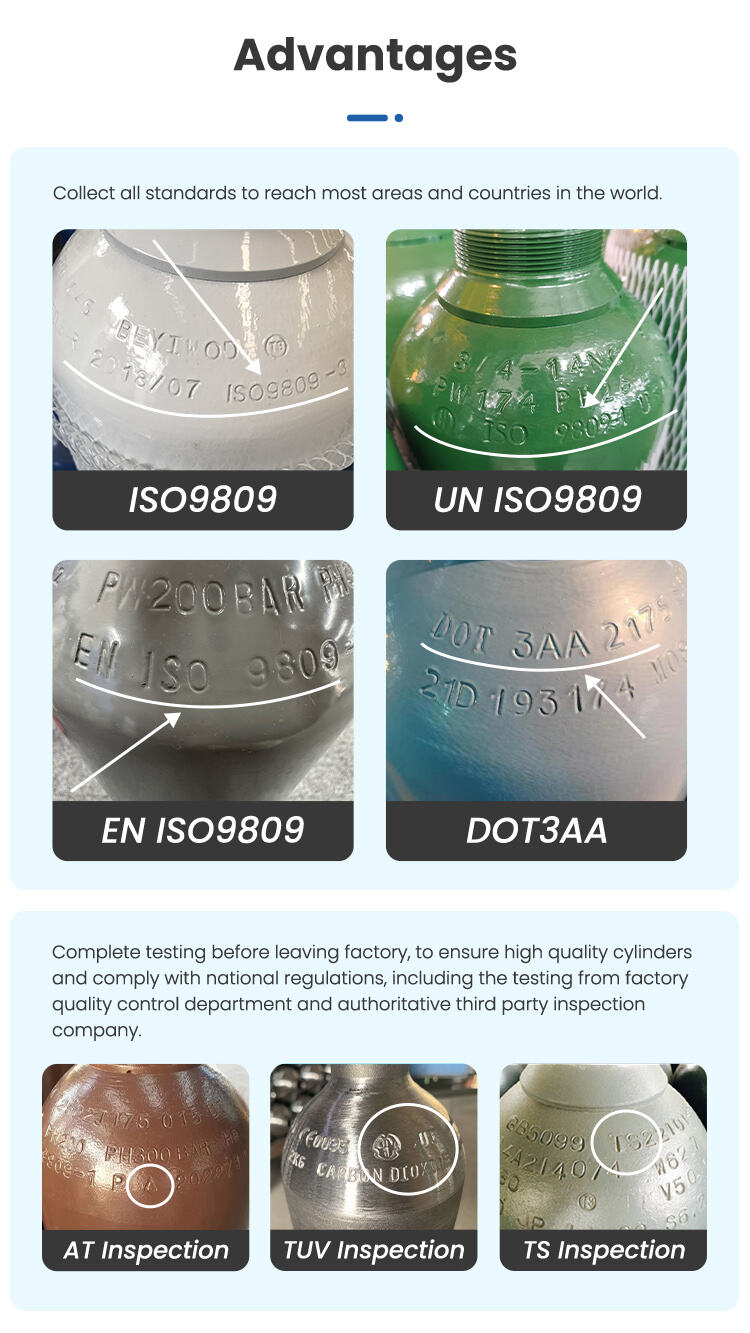

Certification |

ISO9809-1/ISO9809-3 |

Weight without valve |

48kg/50kg/52kg |

Height without valve |

1305mm/1350mm/1430mm |

Model |

Outer Diameter (mm) |

Water Capacity(L) |

Length(mm) |

Weight(kg) |

Working Pressure |

Test Pressure |

Material |

||||||||

BN-108-(2.3-2.68)-2175-L |

108 |

2.3 |

355 |

3.3 |

2175psi |

3625Psi |

30CrMo |

||||||||

2.68 |

400 |

3.7 |

2175psi |

3625Psi |

|||||||||||

BN-133-(3.6-10)-2015-L |

133 |

3.6 |

395 |

6.5 |

2015psi |

3360psi |

30CrMo |

||||||||

10 |

925 |

14 |

|||||||||||||

BN-140-(3.6-10)-2175-L |

140 |

3.6 |

345 |

5.5 |

2175psi |

3625Psi |

30CrMo |

||||||||

6.7 |

570 |

8.5 |

|||||||||||||

10 |

810 |

11.6 |

|||||||||||||

BN-178-(7.8-21.6)-2015-A |

178 |

7.8 |

485 |

11.9 |

2015psi |

3360psi |

30CrMo |

||||||||

15.7 |

845 |

19.6 |

|||||||||||||

21.6 |

1110 |

25.2 |

|||||||||||||

BN-178-(7.8-21.6)-2265-L |

178 |

7.8 |

485 |

11.9 |

2265psi |

3775psi |

30CrMo |

||||||||

15.7 |

845 |

19.6 |

|||||||||||||

21.6 |

1110 |

25.2 |

|||||||||||||

BN-232-(30-58)-2265-L |

232 |

30 |

925 |

36 |

2265psi |

3775psi |

37Mn |

||||||||

47 |

1735 |

51 |

|||||||||||||

58 |

1665 |

61 |

|||||||||||||

BN-232-(30-56)-2175-L |

232 |

30 |

920 |

33 |

2175psi |

3625psi |

37Mn |

||||||||

46 |

1340 |

46.6 |

|||||||||||||

56 |

1600 |

55 |

|||||||||||||

BN-232-(30-58)-2900-L |

232 |

30 |

945 |

42.7 |

2900psi |

4833psi |

30CrMo/37Mn |

||||||||

47 |

1365 |

47.4 |

|||||||||||||

58 |

1705 |

74.3 |

|||||||||||||

BN-232-(43.3-52)-2015-L |

232 |

43.3 |

1270 |

44.4 |

2015psi |

3360psi |

37Mn |

||||||||

47 |

1365 |

47.4 |

|||||||||||||

52 |

1495 |

51.6 |

|||||||||||||

BN-232-(30-58)-2400-L |

232 |

30 |

920 |

37.5 |

2400psi |

4000psi |

37Mn |

||||||||

47 |

1365 |

53 |

|||||||||||||

58 |

1660 |

64 |

|||||||||||||

BN-232-(30-52)-2400-L |

232 |

30 |

925 |

37.5 |

2400psi |

4000psi |

30CrMo |

||||||||

48.8 |

1420 |

55 |

|||||||||||||

52 |

1505 |

58 |

|||||||||||||

BN-267-(58-80)-2130-L |

267 |

58 |

1270 |

60.5 |

2130psi |

3550psi |

30CrMo/37Mn |

||||||||

67.5 |

1460 |

68.5 |

|||||||||||||

68 |

1470 |

69.5 |

|||||||||||||

80 |

1710 |

79.6 |

|||||||||||||

BN-279-(68-90)-2175-L |

279 |

68 |

1355 |

72 |

2175psi |

3625psi |

30CrMo |

||||||||

70 |

1390 |

74 |

|||||||||||||

80 |

1575 |

81 |

|||||||||||||

82 |

1610 |

83 |

|||||||||||||

1630 |

85 |

||||||||||||||

1650 |

86 |

||||||||||||||

87 |

1700 |

87 |

|||||||||||||

90 |

1755 |

89.5 |

Model |

Working Pressuer(bar) |

Test pressure (bar) |

Water Capacity(L) |

Outer Diameter(mm) |

Length(mm) |

Weight(kg) |

BENE108-3-15 |

150 |

250 |

3 |

108 |

480 |

5.7 |

BENE140-4-15 |

150 |

250 |

4 |

140 |

365 |

6.6 |

BENE108-5-15 |

150 |

250 |

5 |

140 |

700 |

7.5 |

BENE140-5-15 |

150 |

250 |

5 |

140 |

440 |

7.7 |

BENE140-6.3-15 |

150 |

250 |

6.3 |

140 |

540 |

9.4 |

BENE140-7-15 |

150 |

250 |

7 |

140 |

600 |

10.8 |

BENE140-8-15 |

150 |

250 |

8 |

140 |

685 |

11 |

BENE140-9-15 |

150 |

250 |

9 |

140 |

745 |

11.5 |

BENE140-10-15 |

150 |

250 |

10 |

140 |

825 |

13.4 |

BENE159-8-15 |

150 |

250 |

8 |

159 |

545 |

11 |

BENE159-10-15 |

150 |

250 |

10 |

159 |

675 |

13 |

BENE159-13.4-15 |

150 |

250 |

13.4 |

159 |

890 |

21 |

BENE180-20-15 |

150 |

250 |

20 |

180 |

985 |

25 |

BENE219-20-15 |

150 |

250 |

20 |

219 |

730 |

27 |

BENE219-40-15 |

150 |

250 |

40 |

219 |

1310 |

48 |

BENE232-50-15 |

150 |

250 |

50 |

232 |

1480 |

60 |

BENE267-68-15 |

150 |

250 |

68 |

267 |

1500 |

74 |

BENE279-80-15 |

150 |

250 |

80 |

279 |

1735 |

91 |

Diameter (in/mm) |

Length(mm) |

Volume(L) |

Weight(kgs) |

Working Pressure (Psi/Bar) |

Test Pressure (Psi/Bar) |

Thread |

|||

105 |

320 |

1.8 |

3.57 |

200/216 |

300/310 |

W19.8 |

|||

345 |

2 |

3.75 |

W28.8 |

||||||

425 |

2.7 |

4.4 |

25E |

||||||

470 |

3 |

4.6 |

25E |

||||||

480 |

3.1 |

4.68 |

25E |

||||||

138 |

470 |

5 |

6.7 |

200/216 |

300/310 |

W28.8 |

|||

500 |

5.4 |

7.8 |

25E |

||||||

545 |

6 |

8.4 |

25E |

||||||

595 |

6.7 |

8.9 |

25E |

||||||

660 |

7.5 |

9.7 |

25E |

||||||

695 |

8 |

10.1 |

25E |

||||||

780 |

9.1 |

11 |

25E |

||||||

800 |

9.4 |

11.3 |

25E |

||||||

845 |

10 |

11.8 |

25E |

||||||

892 |

10.7 |

12.5 |

25E |

||||||

850 |

10 |

17 |

25E |

||||||

159 |

420 |

6 |

10.3 |

200 |

300 |

W28.8 |

|||

475 |

7 |

11.5 |

25E |

||||||

535 |

8 |

12.7 |

25E |

||||||

650 |

10 |

15.1 |

25E |

||||||

937 |

18 |

25.4 |

25E |

||||||

1029 |

20 |

27.7 |

25E |

||||||

200 |

570 |

13.4 |

21.1 |

200 |

300 |

W28.8 |

|||

645 |

15 |

22.4 |

25E |

||||||

815 |

20 |

27.4 |

25E |

||||||

232 |

1250 |

40 |

55 |

200 |

315 |

W28.8 |

|||

232 |

1530 |

50 |

65 |

200 |

300 |

W28.8 |

Type |

Outside Diameter (mm) |

Capacity (L) |

Height (mm) |

Weight (kg) |

Working Pressue (bar) |

Test Pressure (bar) |

Material |

|||||

178-15.7(10-20)L |

178 |

10 |

540 |

13.2 |

154bar |

231bar |

30CrMo |

|||||

15.7 |

810 |

19.6 |

||||||||||

20 |

1020 |

24.7 |

||||||||||

178-21.6(7.8-26)L |

178 |

7.8 |

476 |

10.5 |

174bar |

261bar |

||||||

21.6 |

1317 |

23.0 |

||||||||||

26 |

1858 |

27.0 |

||||||||||

229-45(22-55)L |

229 |

22 |

725 |

36.0 |

300bar |

450bar |

34CrMo4 |

|||||

45 |

1370 |

64.0 |

||||||||||

55 |

1650 |

75.5 |

||||||||||

232-47(22-70)L |

232 |

22 |

696 |

27.5 |

174bar |

261bar |

37Mn |

|||||

47 |

1340 |

49.0 |

||||||||||

70 |

1955 |

69.5 |

||||||||||

232-50(22-70)L |

232 |

22 |

696 |

27.5 |

200bar |

300bar |

34CrMo4 |

|||||

50 |

1430 |

52.0 |

||||||||||

70 |

1955 |

69.5 |

||||||||||

267-68(35-90)L |

267 |

35 |

810 |

41.0 |

174bar |

264bar |

37Mn |

|||||

68 |

1460 |

69.0 |

||||||||||

90 |

1895 |

88.0 |

||||||||||

279-82.5(40-100)L |

279 |

40 |

845 |

47.0 |

167bar |

250bar |

||||||

82.5 |

1620 |

83.5 |

||||||||||

100 |

1935 |

98.0 |

Beyiwod

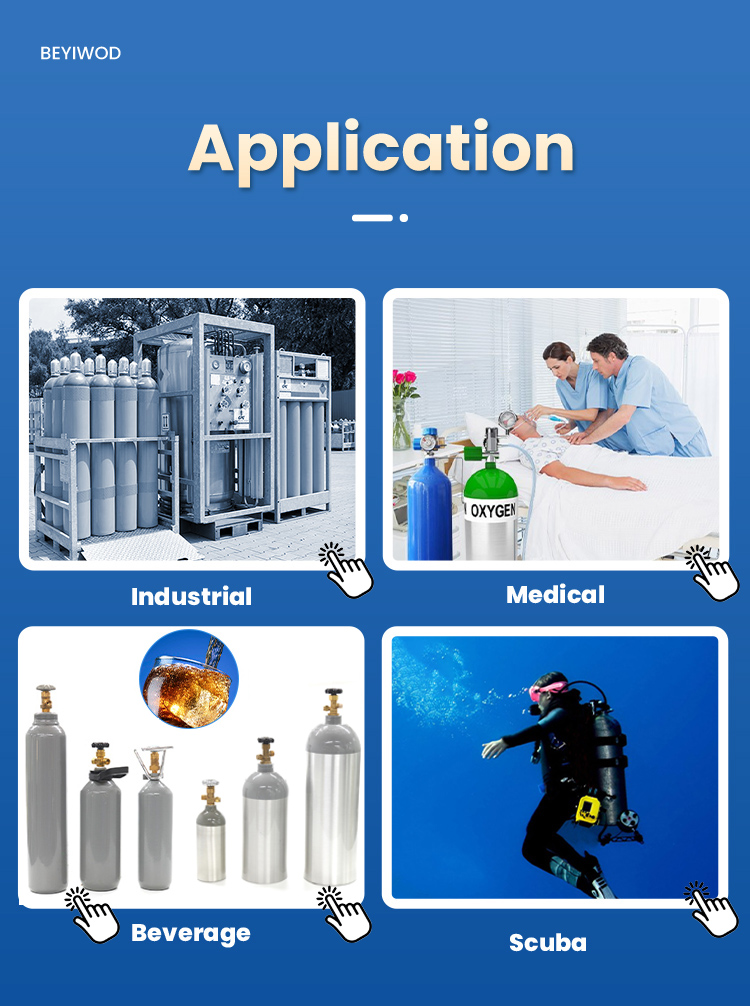

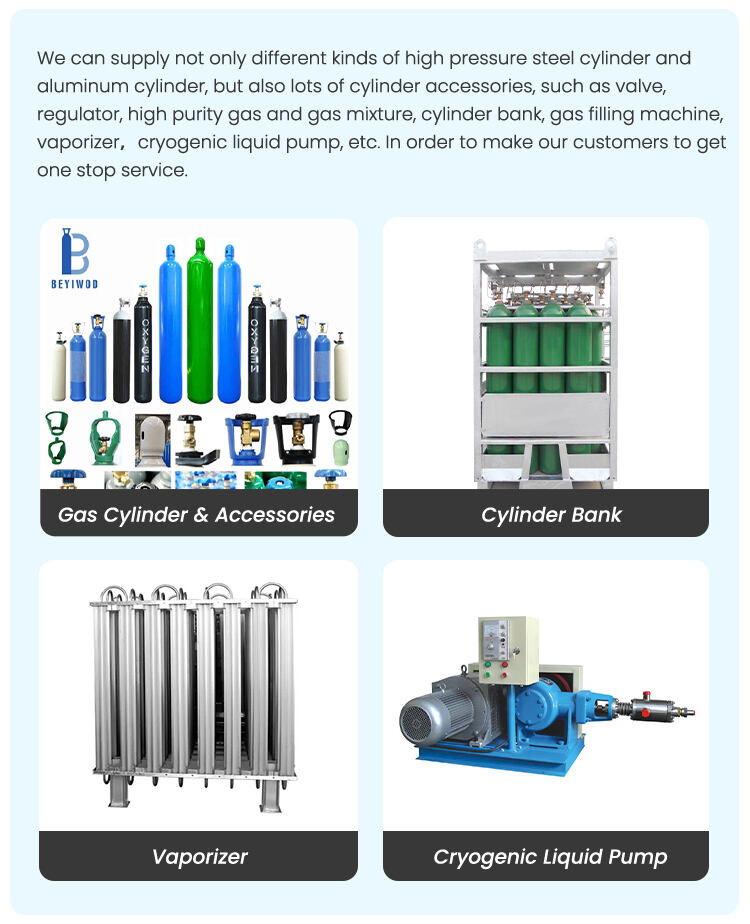

The WP150bar/200bar 40L 47L steel 50L industrial argon cylinder oxygen/co2/nitrogen/argon gas cylinder is truly a top-quality item Beyiwod, designed to focus on your gas requirements. This cylinder comprises steel is industrial-grade which makes it strong, sturdy, and sturdy. This cylinder assures you for this service is long, making you receive your hard money that earned worth featuring its durable design.

This WP150bar/200bar 40L 47L steel 50L commercial argon cylinder oxygen/co2/nitrogen/argon gasoline cylinder will be various sizes for you personally, having a capacity of either 40L, 47L, or 50L. The product shall might be present in handy whether you will require a sizable or cylinder is little. It really well suited for usage with various gases such as argon, oxygen, CO2, and nitrogen.

This WP150bar/200bar 40L 47L metal that is 50L is industrial argon cylinder oxygen/co2/nitrogen/argon gas cylinder is a range that absolutely an excellent applications which can be industrial in terms of instance welding, cutting, and brazing. It offers a secure and storage is reliable when it comes to gases, ensuring if you want them they stay prepared and intact for usage. Having a potent force is potent definitely an operating of to 150bar to 200bar, this cylinder is wonderful for high-pressure applications.

The Beyiwod brand is renowned for providing items are high-quality and also this WP150bar/200bar 40L 47L steel 50L is industrial argon cylinder oxygen/co2/nitrogen/argon gas cylinder isn't any exception. It really designed and constructed to satisfy most of the needed safety and regulations for gasoline space for storage space and transport. Featuring its features which are advanced it really an easy task to trust the product to generate durability performance exceptional and dependability.

The large choice of standout popular features of this WP150bar/200bar 40L 47L steel 50L commercial argon cylinder oxygen/co2/nitrogen/argon fuel cylinder is its safety that definitely an integral valve. This valve really helps you to make sure that the strain inside the cylinder remains stable within the recommended levels, preventing any accidents or problems for equipment. Additionally, the cylinder has a casing that definitely a protective shields it from genuine harm and corrosion, rendering it use is surroundings are appropriate.